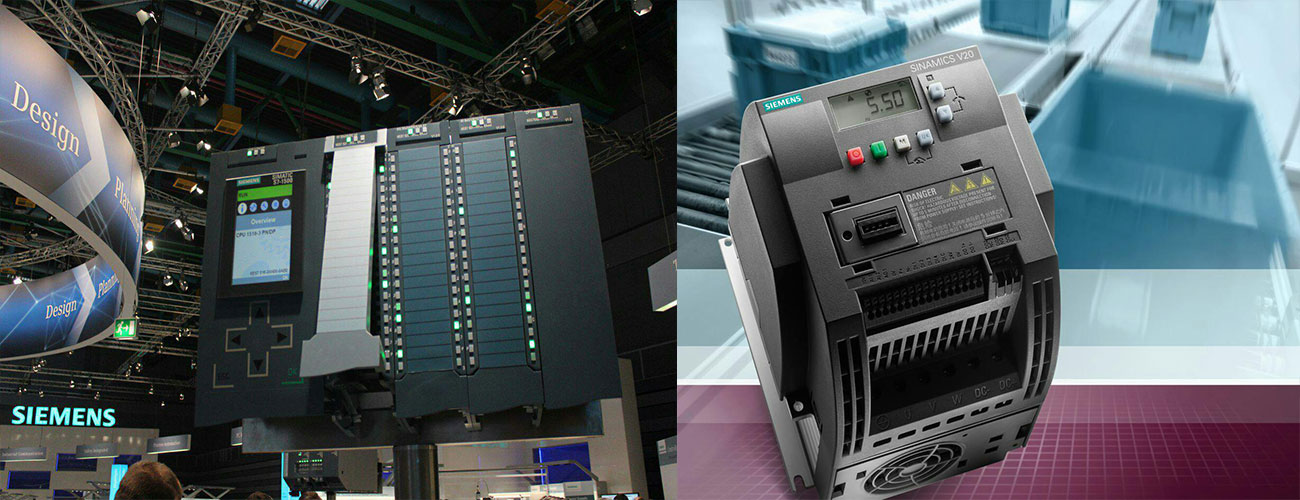

S7-1500

General

The central processing units (CPUs) are the heart of the SIMATIC S7-1500. They execute the user program and network the controller with other automation components.

The following CPUs are available:

CPU-1511-1 PN for small to medium applications

CPU-1513-1 PN for medium applications

CPU 1515-2 PN for medium to large applications

CPU-1516-3 PN/DP for exceptionally demanding applications and additional communication tasks

CPU 1518-4 PN/DP for high-performance applications and shortest reaction times

CPU 1516F-3 PN/DP for demanding standard and fail-safe applications

CPU 1518F-4 PN/DP for demanding standard and fail-safe applications with very high requirements

Features and customer benefits

Thanks to numerous innovations, the CPUs of the SIMATIC S7-1500 deliver the ultimate plus in productivity and efficiency. The hardware is extremely compact. Highly integrated, highly versatile components and modules save space in the cabinet and reduce the spare parts inventory overhead.

Firmware Version 1.5: New features for efficient commissioning and on-site diagnostics

-

Complete station uploading including the assignment of hardware parameters

-

Option handling in the central configuration

-

Shared I-Device

-

Language support for Russian, Japanese, Portuguese, Turkish and Korean on the display

-

Watch tables and force table directly on the display for fast on-site diagnostics

Maximum performance

-

Shortest possible machine response times for enhanced productivity (control quality)

-

Short cycle times for greater productivity

-

Expansion of the program scope within the same cycle time

Display for commissioning and diagnostics

-

Shorter downtimes thanks to plain-text diagnostic information on central and decentralized modules

-

Adaptation of customer-specific network settings without on-site programming

-

Display can be unplugged and plugged during operation

-

Password assignment for display operation via TIA Portal

-

Long service life of 50,000 operating hours

PROFINET standard on every CPU

-

PN IRT (V2.2) ensures defined response times and highly precise machine behavior

-

Additional Ethernet interface on high-end CPU for optimum integration in plant network

-

Web server for simple display of service and diagnostic information

Innovative memory concept

-

Sufficient memory for any application, regardless of industry

-

Flexible memory card concept for varying project sizes

-

High storage capacity: up to 2 GB card for project data, archives, recipes and documents

-

Optimized data modules for variably granular selection of values for remanent storage.

Optimized diagnostic concept

-

Efficient fault analysis using a uniform display concept for STEP 7, HMI, Web server, display on CPU

-

Consistently integrated system diagnostics, no additional project planning overhead even for machine expansion

-

No loss of system error messages, not even when CPU is in stop

STEP 7 language innovation

-

Completely symbolic programming for better comprehensibility

-

Enhanced compiler performance for shorter cycle times

-

Greater precision e.g. for technology thanks to support for all 64-bit data types in all IEC languages

-

Consistent download with all program changes

-

Simplification of complex mathematic operations thanks to the Calculate box in LAD and function plan

Security Integrated

-

Optimized security even against unauthorized access via HMI with controller security level mechanism

-

Investment protection thanks to security for components and programs

-

High machine availability thanks to integrity and confidentiality protection of project planning data, firmware file and secure communication

Compatibility/plug & play

-

Investment protection of existing know-how thanks to reusability of programs on all S7-1500 CPUs and integrated migration tool for existing S7 projects

-

Rapid, error-free identification of hardware through upload to Engineering

-

Service possible even without current project through complete project upload with symbols

Integrated technology

-

Integration of Standard Motion Control with flexible connection of all PROFIdrive-enabled drives

-

Standardized PLCopen components for simple project realization

-

TRACE: cycle-granular recording of up to 16 variables for precise optimization of control programs and drives

-

Recording in separate CPU memory area for simple localization of sporadic errors

-

Integrated PID controller for simple closed-loop control tasks: time savings thanks to optimized control parameter optimization for optimum control quality (PID controller)

-

PID Compact/PID 3-Step: continuous controller with analog or pulse width-modulated output and special step controller for external actuators (e.g. valves) with autotuning

Datalog (archive) and recipes

-

Easy access to all machine-relevant operating data using Office tools and via Web server

-

Easy access to machine configuration data via Web browser or SD card reader (bidirectional data interchange to and from controller)

Safety Integrated

-

One controller, one engineering, one communication for standard and fail-safe automation

-

Status display or diagnostic alarms without PG

-

SIMATIC S7-1518F – The most powerful controller for standard and fail-safe automation

To the top of the page

TECHNICAL DATA :

| SIMATIC S7-1500 Central processing units |

Catalog ST 70:

You can also find information about SIMATIC S7-1500 in the Catalog ST 70:

http://www.automation.siemens.com/salesmaterial-as/catalog/en/simatic_st70_chap04_english_2013.pdf

Further information and downloads

Manuals

The SIMATIC S7-1500 manuals can be downloaded free of charge from the Internet (SIMATIC Customer Support).

http://support.automation.siemens.com/WW/view/en/86140384

SIMATIC S7-1500 Display Simulator

Using the Display Simulator of the S7-1500, you can become familiar in advance with the different setting options and functions on the display.

http://www.automation.siemens.com/salesmaterial-as/interactive-manuals/getting-started_simatic-s7-1500/disp_tool/start_en.html

Safety Integrated

Information on functional safety, including for S7-1500F controllers:

http://www.siemens.com/safety-integrated

General information

http://www.siemens.com/S7-1500

SIMATIC Selection Tool

http://www.siemens.com/tia-selection-tool

Brochures

Information material for downloading can be found on the Internet:

http://www.siemens.com/simatic/printmaterial

|

General

The central processing units (CPUs) are the heart of the SIMATIC S7-1500. They execute the user program and network the controller with other automation components.

The following CPUs are available:

CPU-1511-1 PN for small to medium applications

CPU-1513-1 PN for medium applications

CPU 1515-2 PN for medium to large applications

CPU-1516-3 PN/DP for exceptionally demanding applications and additional communication tasks

CPU 1518-4 PN/DP for high-performance applications and shortest reaction times

CPU 1516F-3 PN/DP for demanding standard and fail-safe applications

CPU 1518F-4 PN/DP for demanding standard and fail-safe applications with very high requirements

Features and customer benefits

Thanks to numerous innovations, the CPUs of the SIMATIC S7-1500 deliver the ultimate plus in productivity and efficiency. The hardware is extremely compact. Highly integrated, highly versatile components and modules save space in the cabinet and reduce the spare parts inventory overhead.

Firmware Version 1.5: New features for efficient commissioning and on-site diagnostics

-

Complete station uploading including the assignment of hardware parameters

-

Option handling in the central configuration

-

Shared I-Device

-

Language support for Russian, Japanese, Portuguese, Turkish and Korean on the display

-

Watch tables and force table directly on the display for fast on-site diagnostics

Maximum performance

-

Shortest possible machine response times for enhanced productivity (control quality)

-

Short cycle times for greater productivity

-

Expansion of the program scope within the same cycle time

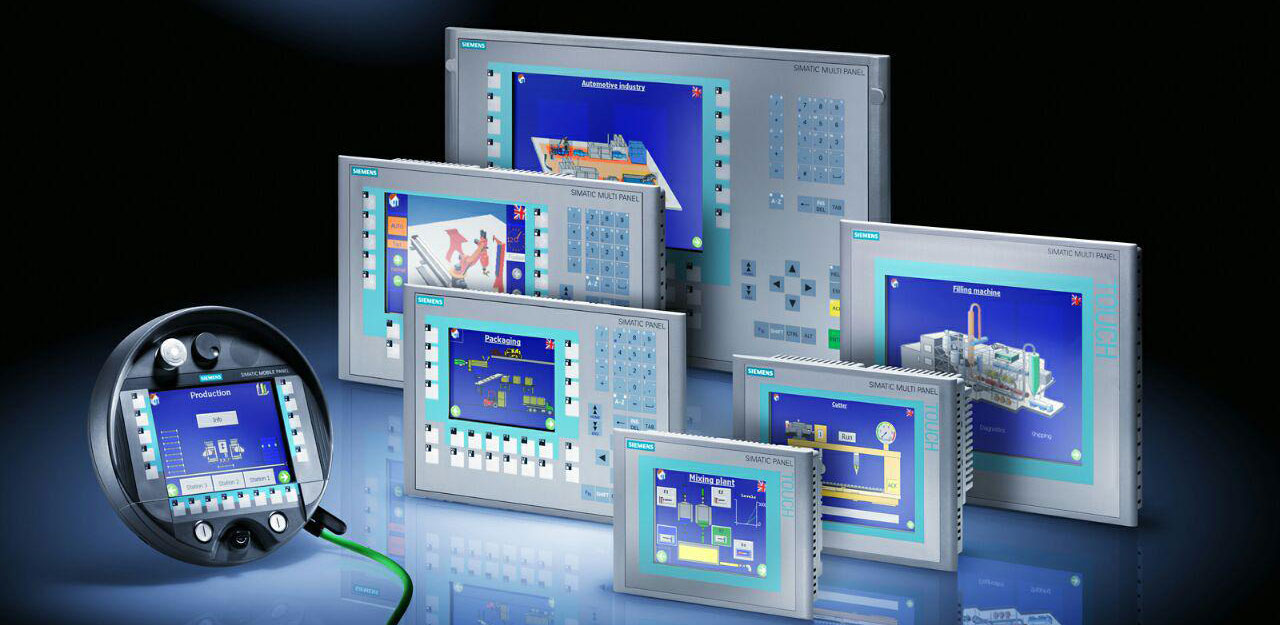

Display for commissioning and diagnostics

-

Shorter downtimes thanks to plain-text diagnostic information on central and decentralized modules

-

Adaptation of customer-specific network settings without on-site programming

-

Display can be unplugged and plugged during operation

-

Password assignment for display operation via TIA Portal

-

Long service life of 50,000 operating hours

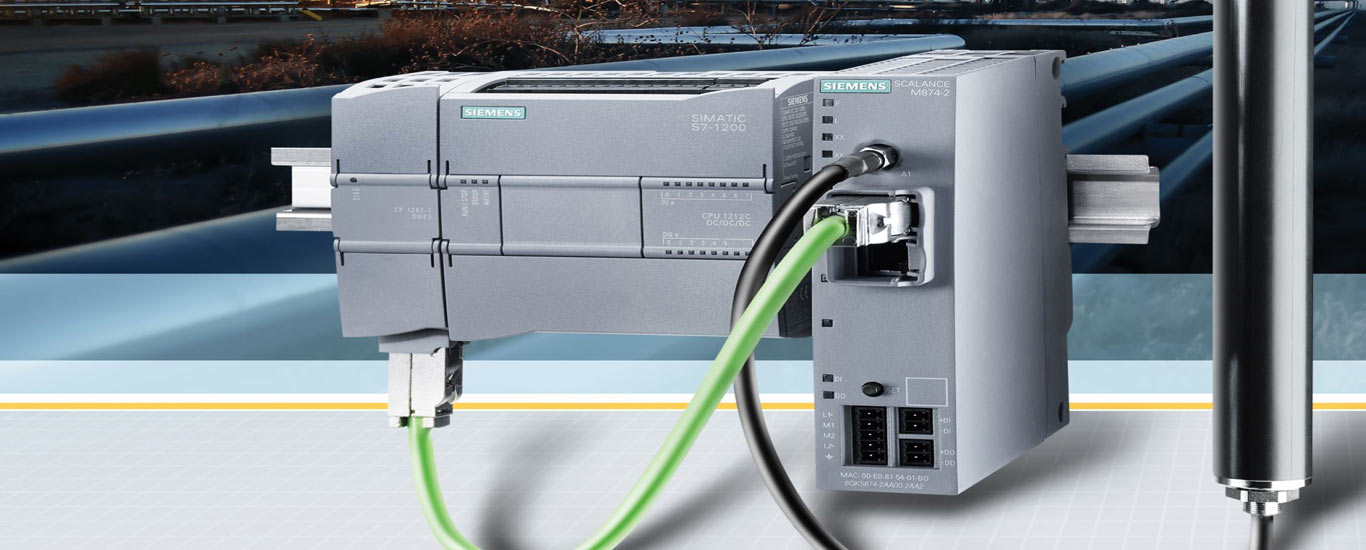

PROFINET standard on every CPU

-

PN IRT (V2.2) ensures defined response times and highly precise machine behavior

-

Additional Ethernet interface on high-end CPU for optimum integration in plant network

-

Web server for simple display of service and diagnostic information

Innovative memory concept

-

Sufficient memory for any application, regardless of industry

-

Flexible memory card concept for varying project sizes

-

High storage capacity: up to 2 GB card for project data, archives, recipes and documents

-

Optimized data modules for variably granular selection of values for remanent storage.

Optimized diagnostic concept

-

Efficient fault analysis using a uniform display concept for STEP 7, HMI, Web server, display on CPU

-

Consistently integrated system diagnostics, no additional project planning overhead even for machine expansion

-

No loss of system error messages, not even when CPU is in stop

STEP 7 language innovation

-

Completely symbolic programming for better comprehensibility

-

Enhanced compiler performance for shorter cycle times

-

Greater precision e.g. for technology thanks to support for all 64-bit data types in all IEC languages

-

Consistent download with all program changes

-

Simplification of complex mathematic operations thanks to the Calculate box in LAD and function plan

Security Integrated

-

Optimized security even against unauthorized access via HMI with controller security level mechanism

-

Investment protection thanks to security for components and programs

-

High machine availability thanks to integrity and confidentiality protection of project planning data, firmware file and secure communication

Compatibility/plug & play

-

Investment protection of existing know-how thanks to reusability of programs on all S7-1500 CPUs and integrated migration tool for existing S7 projects

-

Rapid, error-free identification of hardware through upload to Engineering

-

Service possible even without current project through complete project upload with symbols

Integrated technology

-

Integration of Standard Motion Control with flexible connection of all PROFIdrive-enabled drives

-

Standardized PLCopen components for simple project realization

-

TRACE: cycle-granular recording of up to 16 variables for precise optimization of control programs and drives

-

Recording in separate CPU memory area for simple localization of sporadic errors

-

Integrated PID controller for simple closed-loop control tasks: time savings thanks to optimized control parameter optimization for optimum control quality (PID controller)

-

PID Compact/PID 3-Step: continuous controller with analog or pulse width-modulated output and special step controller for external actuators (e.g. valves) with autotuning

Datalog (archive) and recipes

-

Easy access to all machine-relevant operating data using Office tools and via Web server

-

Easy access to machine configuration data via Web browser or SD card reader (bidirectional data interchange to and from controller)

Safety Integrated

-

One controller, one engineering, one communication for standard and fail-safe automation

-

Status display or diagnostic alarms without PG

-

SIMATIC S7-1518F – The most powerful controller for standard and fail-safe automation

To the top of the page

TECHNICAL DATA :

| SIMATIC S7-1500 Central processing units |

Catalog ST 70:

You can also find information about SIMATIC S7-1500 in the Catalog ST 70:

http://www.automation.siemens.com/salesmaterial-as/catalog/en/simatic_st70_chap04_english_2013.pdf

Further information and downloads

Manuals

The SIMATIC S7-1500 manuals can be downloaded free of charge from the Internet (SIMATIC Customer Support).

http://support.automation.siemens.com/WW/view/en/86140384

SIMATIC S7-1500 Display Simulator

Using the Display Simulator of the S7-1500, you can become familiar in advance with the different setting options and functions on the display.

http://www.automation.siemens.com/salesmaterial-as/interactive-manuals/getting-started_simatic-s7-1500/disp_tool/start_en.html

Safety Integrated

Information on functional safety, including for S7-1500F controllers:

http://www.siemens.com/safety-integrated

General information

http://www.siemens.com/S7-1500

SIMATIC Selection Tool

http://www.siemens.com/tia-selection-tool

Brochures

Information material for downloading can be found on the Internet:

http://www.siemens.com/simatic/printmaterial

|

.jpg)

.jpg)